- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

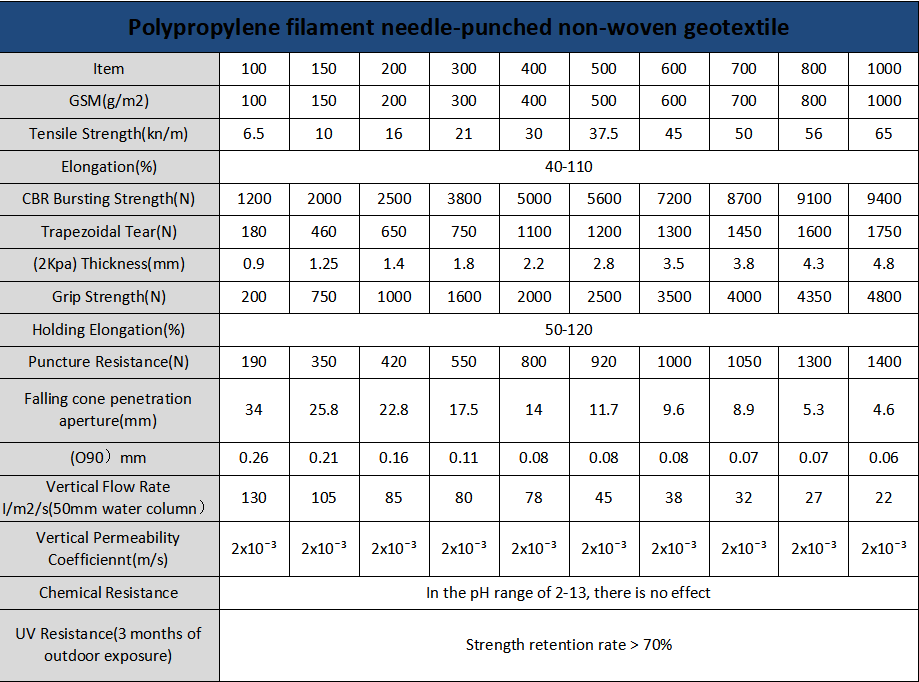

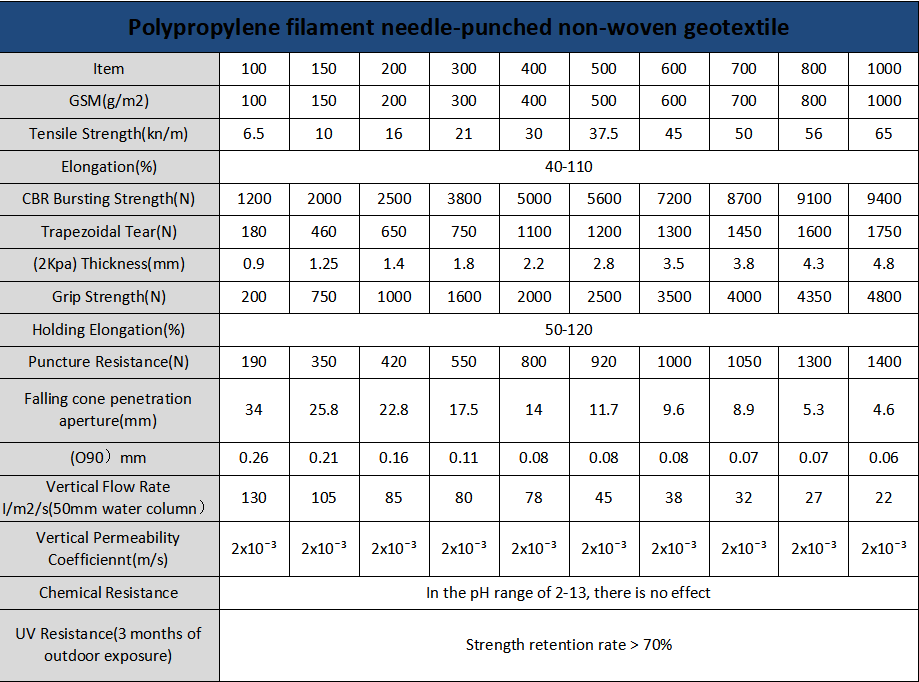

Polypropylene filament geotextile adopts advanced spinning equipment, the monofilament fineness can reach above 11dex, the strength can reach above 3.5gd, the mesh is evenly laid without cloud spots, the vertical and horizontal strength and elongation are consistent, and the product performance is more uniform and stable.

| Keyword: | |

|---|---|

| Application: | |

| Material: | |

| Color: | |

| Usage: | |

| Width: | |

| Length: | |

| Availability: | |

| Quantity: | |

geotextile

Polypropylene filament geotextile

Polypropylene filament geotextile adopts advanced spinning equipment, the monofilament fineness can reach above 11dex, the strength can reach above 3.5gd, the mesh is evenly laid without cloud spots, the vertical and horizontal strength and elongation are consistent, and the product performance is more uniform and stable.

(1) The density of polypropylene is small, only 0.91g/cm3( polyester is 138g/cm3), so compared with polyester geotextile, polypropylene geotextile has a larger coverage area under the same strength.

(2) The special structure of polypropylene makes it have excellent acid and alkali resistance, especially the alkali resistance is better than that of polyester. in polyester.

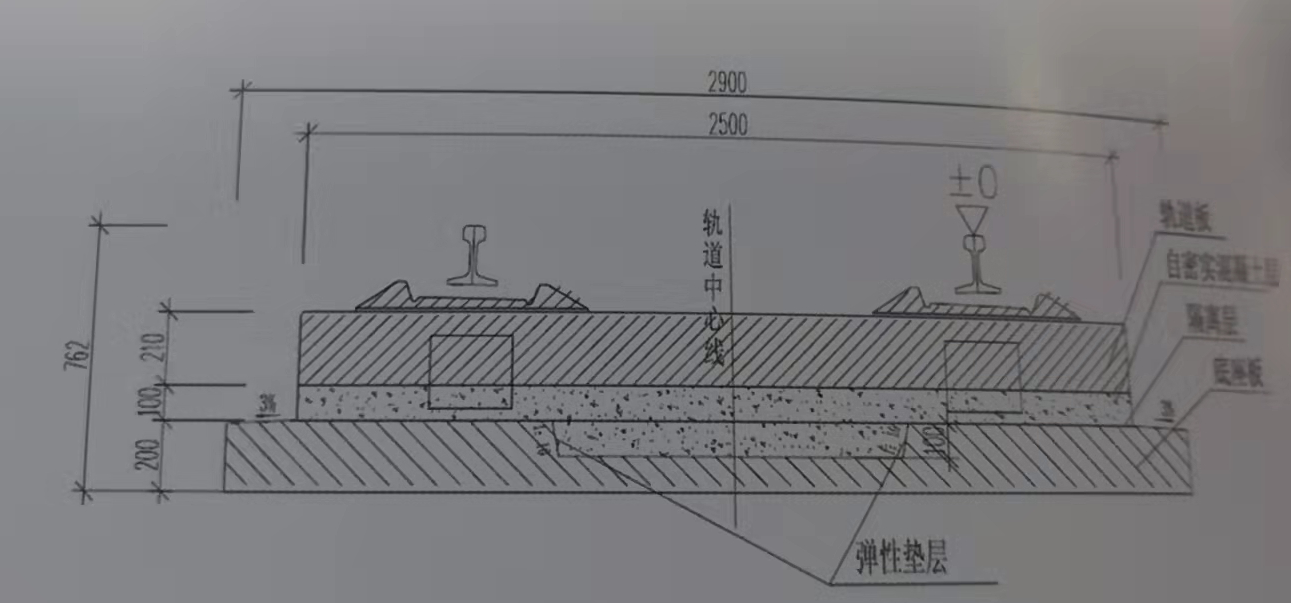

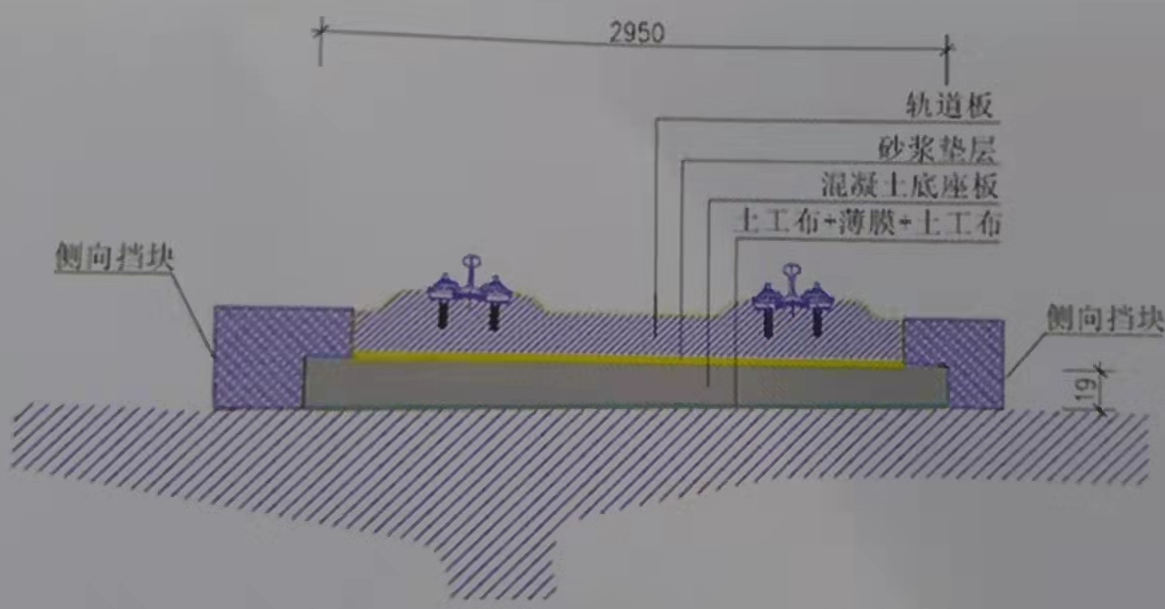

Polypropylene spunbond needle-punched geotextile has superior physical properties and good chemical stability, therefore, it is suitable for any geotechnical engineering, especially in acid and alkaline environments. Such as: highways, railways (high-speed rail), airports, seaports, landfills, tailings dams, fly ash landfills, ash dam pools, artificial wetlands, rivers, lakes and seas, reservoirs, canals, land reclamation, sewage governance and other projects.

Application In Environmental Protection Works:

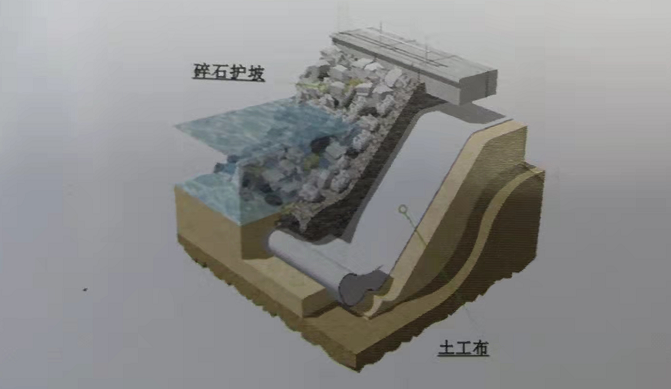

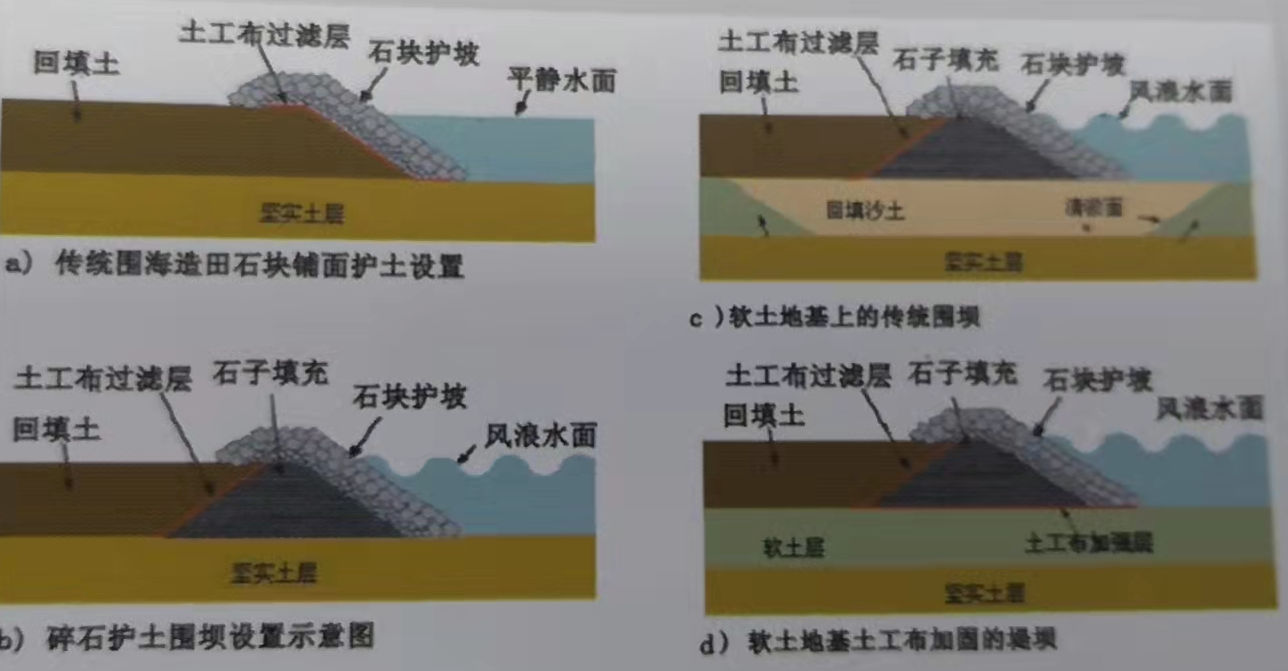

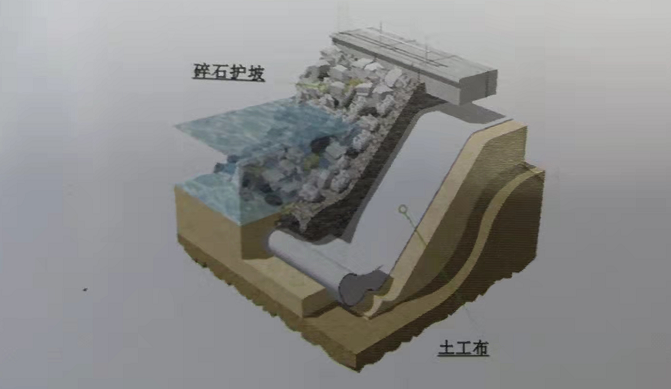

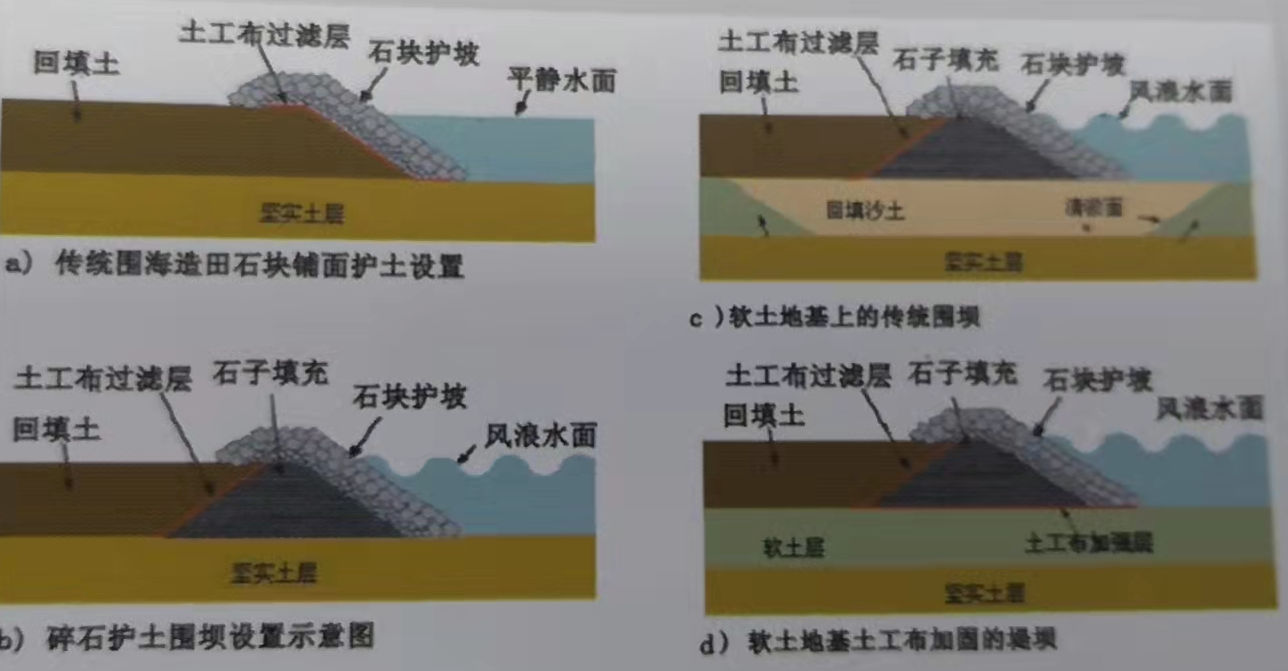

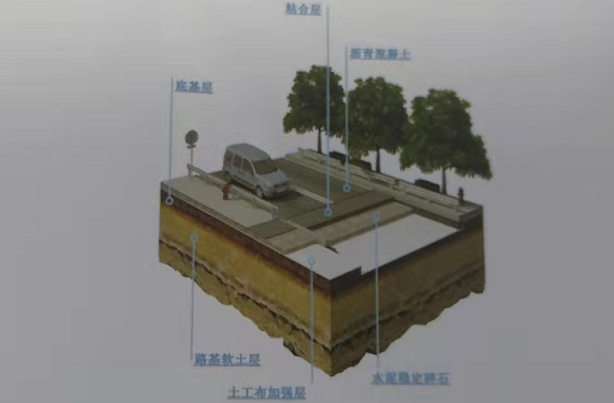

Applicaton of PP Spunbond Needle-Punched Geotextile in reclamation project

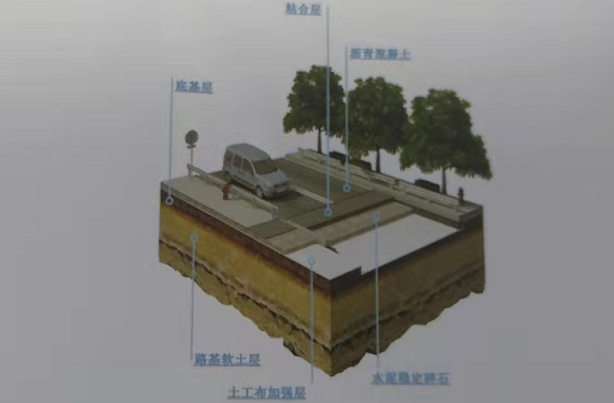

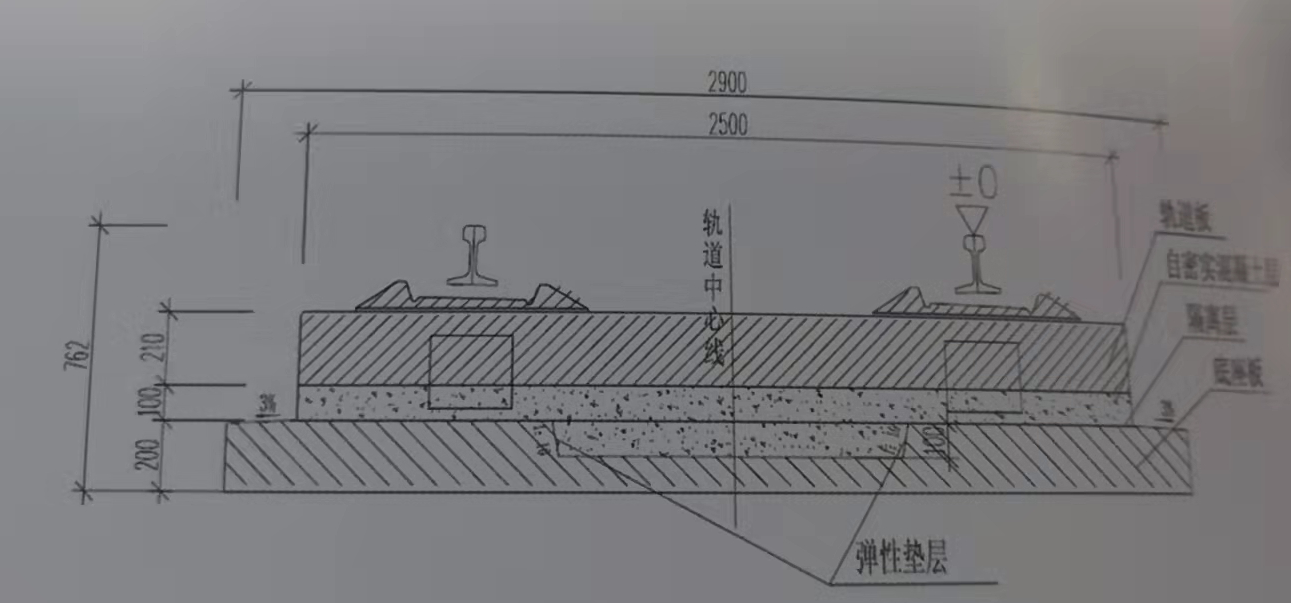

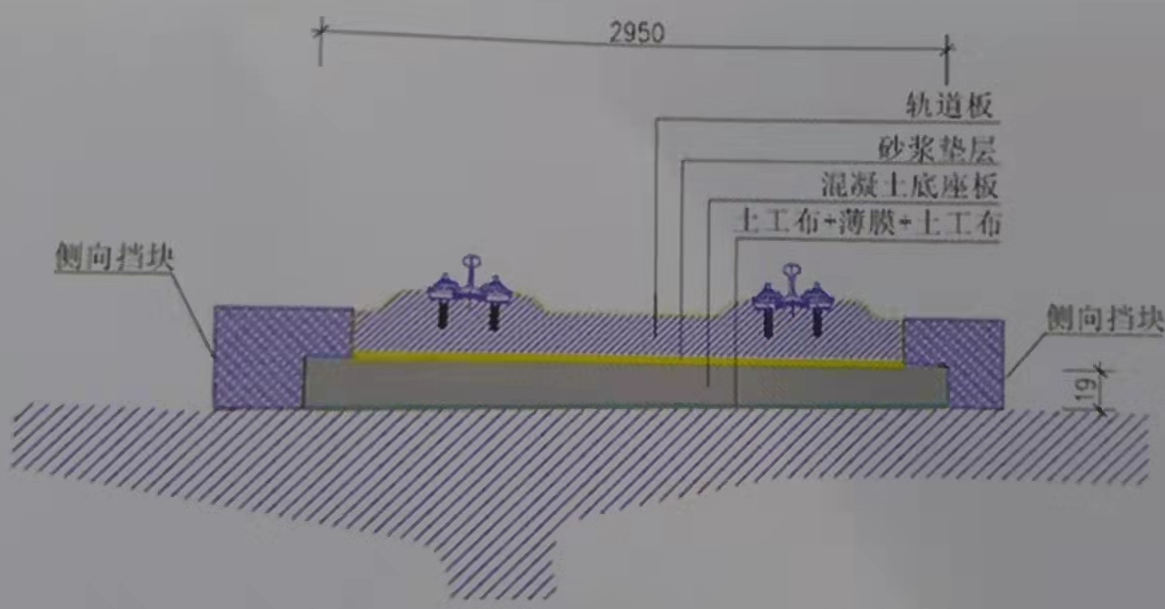

Applicaton of PP Spunbond Needle-Punched Geotextile In Internation Airport Extension Project.

Geotextile Process:

Polypropylene filament geotextile adopts advanced spinning equipment, the monofilament fineness can reach above 11dex, the strength can reach above 3.5gd, the mesh is evenly laid without cloud spots, the vertical and horizontal strength and elongation are consistent, and the product performance is more uniform and stable.

(1) The density of polypropylene is small, only 0.91g/cm3( polyester is 138g/cm3), so compared with polyester geotextile, polypropylene geotextile has a larger coverage area under the same strength.

(2) The special structure of polypropylene makes it have excellent acid and alkali resistance, especially the alkali resistance is better than that of polyester. in polyester.

Polypropylene spunbond needle-punched geotextile has superior physical properties and good chemical stability, therefore, it is suitable for any geotechnical engineering, especially in acid and alkaline environments. Such as: highways, railways (high-speed rail), airports, seaports, landfills, tailings dams, fly ash landfills, ash dam pools, artificial wetlands, rivers, lakes and seas, reservoirs, canals, land reclamation, sewage governance and other projects.

Application In Environmental Protection Works:

Applicaton of PP Spunbond Needle-Punched Geotextile in reclamation project

Applicaton of PP Spunbond Needle-Punched Geotextile In Internation Airport Extension Project.

Geotextile Process: